Introduction to Flange/Valve Inspection and Function.

Objective:

This course was developed to provide necessary qualification, training and testing for NDT Company

personnel involve in the verification, evaluation and interpretation of the final inspection for Flange and

Valves.

Intended to qualified and develop skills of inspectors who conduct NDT and acceptance tests on Flange and

Valves based on applicable standards through check lists, procedures, OEM to verification and evaluation.

Also to enhance the basics information and knowledge including:

- Types of discontinuities categories according to the stage of manufacture/use: Inherent Process,Primary Process, Secondary Process, Services Discontinuities.

- Overview for Manufacturing Processes for Casting and Forging and a description originated defects their causes.

- Pipe Flanges and Flanged Fittings Inspection.

- Flanges of type ASME RF and ASME FF designs and drawing engineer.

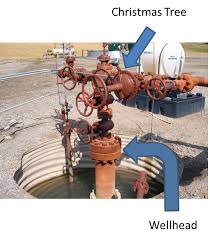

- Casing head and Tubing head design& function.

- Overview to applicable standards.

- General Safety Practices Including: Job Safety Analysis JSA, Tool Box Talks (TBT), Work Permit System, General Safety Awareness.

You will learn:

- The purpose of NDT and an overview information about the NDT general methods ,principal,advantage and disadvantage.

- What is the different between Code, Standard and Specification?

- Conditions leading to defects and failures and Types of Discontinuities.

- The basic of a flange and Gasket (Types, dimensions and inspection).

- Casing head, Spool, Hanger design& function.

- Tubing head, Head Adapter, Hanger design& function

- Overview for applicable standards.

This course for:

- OCTG Inspection Company

- Well Head manufacturing and repair technicians.

- Production well Crews

- Junior engineer whose work in oilfield.